加工条件詳細

2D図面加工品(金属部品(板金・シム))における、対応可能な穴加工の種類や加工限界について記載しています。

穴加工の種類

本サービスの通常納期にて対応可能な各種穴は、通し穴、長穴、角穴の他に、以下の各種穴に対応しています。

※「 加工限界の範囲」もあわせてご確認ください。

タップ穴(並目)

タップ穴(並目)の規格

鉄・圧延鋼板

ステンレス

アルミ

銅・銅合金

鉄・圧延鋼板

| 材質 | 板厚 | タップ穴径 | |||||

|---|---|---|---|---|---|---|---|

| M3 | M4 | M5 | M6 | M8 | M10 | ||

SS400

SPCC | 0.6 | – | – | – | – | – | – |

| 0.8 | ● | – | – | – | – | – | |

| 1.0 | ● | – | – | – | – | – | |

| 1.2 | ● | – | – | – | – | – | |

| 1.6 | ● | ● | ● | – | – | – | |

| 2.0 | ● | ● | ● | ● | – | – | |

| 2.3 | ● | ● | ● | ● | – | – | |

| 3.2 | ● | ● | ● | ● | ● | – | |

| 4.5 | ● | ● | ● | ● | ● | ● | |

| 6.0 | – | ● | ● | ● | ● | ● | |

| 9.0 | – | – | – | ● | ● | ● | |

ステンレス

| 材質 | 板厚 | タップ穴径 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | ||

| SUS304-2B SUS304-#400 SUS304-#800 SUS304-BA SUS304-HL SUS304-No.1 SUS316 SUS430-2B |

0.3 | – | – | – | – | – | – | – | – | – |

| 0.4 | – | – | – | – | – | – | – | – | – | |

| 0.5 | – | – | – | – | – | – | – | – | – | |

| 0.6 | – | – | – | – | – | – | – | – | – | |

| 0.8 | ● | – | – | – | – | – | – | – | – | |

| 1.0 | ● | – | – | – | – | – | – | – | – | |

| 1.2 | ● | – | – | – | – | – | – | – | – | |

| 1.5 | ● | ● | – | – | – | – | – | – | – | |

| 2.0 | ● | ● | ● | ● | – | – | – | – | – | |

| 2.5 | ● | ● | ● | ● | – | – | – | – | – | |

| 3.0 | ● | ● | ● | ● | ● | – | – | – | – | |

| 4.0 | ● | ● | ● | ● | ● | ● | – | – | – | |

| 5.0 | – | ● | ● | ● | ● | ● | – | – | – | |

| 6.0 | – | – | ● | ● | ● | ● | – | – | – | |

| 8.0 | – | – | ● | ● | ● | ● | – | – | – | |

| 9.0 | – | – | – | ● | ● | ● | – | – | – | |

| 10.0 | – | – | – | ● | ● | ● | – | – | – | |

| 12.0 | – | – | – | – | – | – | – | – | – | |

アルミ

| 材質 | 板厚 | タップ穴径 | |||||

|---|---|---|---|---|---|---|---|

| M3 | M4 | M5 | M6 | M8 | M10 | ||

| A1050 A1100 A2017 A5052 |

0.3 | – | – | – | – | – | – |

| 0.5 | – | – | – | – | – | – | |

| 0.6 | – | – | – | – | – | – | |

| 0.8 | ● | – | – | – | – | – | |

| 1.0 | ● | – | – | – | – | – | |

| 1.2 | ● | – | – | – | – | – | |

| 1.5 | ● | ● | – | – | – | – | |

| 2.0 | ● | ● | ● | – | – | – | |

| 2.5 | ● | ● | ● | – | – | – | |

| 3.0 | ● | ● | ● | ● | – | – | |

| 4.0 | ● | ● | ● | ● | ● | – | |

| 5.0 | ● | ● | ● | ● | ● | – | |

| 6.0 | – | – | – | – | – | – | |

銅・銅合金

| 材質 | 板厚 | タップ穴径 | |||||

|---|---|---|---|---|---|---|---|

| M3 | M4 | M5 | M6 | M8 | M10 | ||

| C1020 C1100 C2801 C5191 |

0.2 | – | – | – | – | – | – |

| 0.3 | – | – | – | – | – | – | |

| 0.4 | – | – | – | – | – | – | |

| 0.5 | – | – | – | – | – | – | |

| 0.6 | – | – | – | – | – | – | |

| 0.8 | – | – | – | – | – | – | |

| 1.0 | ● | ● | – | – | – | – | |

| 1.2 | ● | ● | – | – | – | – | |

| 1.5 | ● | ● | – | – | – | – | |

| 2.0 | ● | ● | ● | – | – | – | |

| 2.5 | ● | ● | ● | – | – | – | |

| 3.0 | ● | ● | ● | ● | – | – | |

| 4.0 | ● | ● | ● | ● | ● | – | |

| 5.0 | ● | ● | ● | ● | ● | – | |

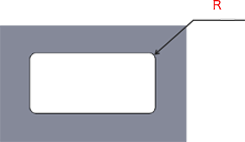

バーリングタップ(並目)

バーリングタップ(並目)の規格

| 部位例 | 加工条件 |

|---|---|

形状例1

| 立ち上がり部に R 形状があることをご了承下さい。 フランジ高さ H と厚み t は板厚以下となります。 |

圧延鋼板

ステンレス

アルミ

銅・銅合金

圧延鋼板

| 材質 | 板厚 | バーリングタップ穴径 | ||

|---|---|---|---|---|

| M3 | M4 | M5 | ||

| SPCC SPHC SECC SEHC SGCC |

0.8 | ● | ● | – |

| 1.0 | ● | ● | ● | |

| 1.2 | ● | ● | ● | |

| 1.6 | ● | ● | ● | |

ステンレス

| 材質 | 板厚 | バーリングタップ穴径 | ||

|---|---|---|---|---|

| M3 | M4 | M5 | ||

| SUS304-2B SUS304-#400 SUS304-#800 SUS304-BA SUS304-HL SUS304-No.1 SUS316 SUS430-2B |

0.8 | ● | ● | – |

| 1.0 | ● | ● | ● | |

| 1.2 | ● | ● | ● | |

| 1.5 | ● | ● | ● | |

アルミ

| 材質 | 板厚 | バーリングタップ穴径 | ||

|---|---|---|---|---|

| M3 | M4 | M5 | ||

| A1050 A1100 A2017 A5052 |

0.8 | ● | ● | – |

| 1.0 | ● | ● | ● | |

| 1.2 | ● | ● | ● | |

| 1.5 | ● | ● | ● | |

銅・銅合金

| 材質 | 板厚 | バーリングタップ穴径 | ||

|---|---|---|---|---|

| M3 | M4 | M5 | ||

| C1020 C1100 C2801 C5191 |

0.8 | ● | ● | – |

| 1.0 | ● | ● | ● | |

| 1.2 | ● | ● | ● | |

| 1.5 | ● | ● | ● | |

皿穴

| 部位例 | 加工条件 |

|---|---|

| 皿(円錐形状)の角度は90°で設計してください。 穴径の比率 D/d は、d が4.0mm以下のとき1.4を超える比率、 d が4.0mm超のとき1.7を超える比率にて設計してください。 |

材質・板厚ごとに対応可能なサイズが異なりますので、下表をご確認ください。

鉄・圧延鋼板

ステンレス

アルミ

銅・銅合金

鉄・圧延鋼板

| 材質 | 板厚 | タップ穴径 | |||||

|---|---|---|---|---|---|---|---|

| M3 | M4 | M5 | M6 | M8 | M10 | ||

SS400

| 2.0 | ● | – | – | – | – | – |

| 2.3 | ● | – | – | – | – | – | |

| 3.2 | ● | ● | ● | – | – | – | |

| 4.5 | ● | ● | ● | ● | – | – | |

| 6.0 | ● | ● | ● | ● | ● | ● | |

| 9.0 | – | – | ● | ● | ● | ● | |

ステンレス

| 材質 | 板厚 | タップ穴径 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | ||

| SUS304-2B SUS304-#400 SUS304-#800 SUS304-BA SUS304-HL SUS304-No.1 SUS316 SUS430-2B |

2.0 | ● | – | – | – | – | – | – | – | – |

| 2.5 | ● | – | – | – | – | – | – | – | – | |

| 3.0 | ● | ● | ● | – | – | – | – | – | – | |

| 4.0 | ● | ● | ● | ● | – | – | – | – | – | |

| 5.0 | ● | ● | ● | ● | ● | – | – | – | – | |

| 6.0 | – | ● | ● | ● | ● | – | – | – | – | |

| 9.0 | – | – | ● | ● | ● | ● | ● | ● | ● | |

| 10.0 | – | – | ● | ● | ● | ● | ● | ● | ● | |

| 12.0 | – | – | ● | ● | ● | ● | ● | ● | ● | |

アルミ

| 材質 | 板厚 | タップ穴径 | ||||

|---|---|---|---|---|---|---|

| M3 | M4 | M5 | M6 | M8 | ||

| A1050 A1100 A2017 A5052 |

2.0 | ● | – | – | – | – |

| 2.5 | ● | – | – | – | – | |

| 3.0 | ● | ● | ● | – | – | |

| 4.0 | ● | ● | ● | ● | – | |

| 5.0 | ● | ● | ● | ● | ● | |

| 6.0 | ● | ● | ● | ● | ● | |

銅・銅合金

| 材質 | 板厚 | タップ穴径 | |||||

|---|---|---|---|---|---|---|---|

| M3 | M4 | M5 | M6 | M8 | M10 | ||

| C1020 C1100 C2801 C5191 |

2.0 | ● | – | – | – | – | – |

| 2.5 | ● | – | – | – | – | – | |

| 3.0 | ● | ● | ● | – | – | – | |

| 4.0 | ● | ● | ● | ● | ● | – | |

| 5.0 | ● | ● | ● | ● | ● | – | |

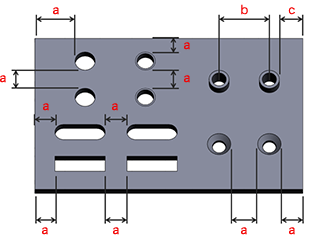

加工限界の範囲

穴と端面・穴間の最小距離

| 板厚 | 材質 | 限界値a | 限界値b | 限界値c | |||

|---|---|---|---|---|---|---|---|

SS400

| SUS304-2B SUS304-#400 SUS304-#800 SUS304-BA SUS304-HL SUS304-No.1 SUS316 SUS430-2B | A1050 A1100 A2017 A5052 | C1020 C1100 C2801 C5191 | ||||

| 0.2 | – | – | – | – | – | – | – |

| 0.3 | – | – | – | – | – | – | – |

| 0.4 | – | ● | – | – | 0.9 | 11.5 | 3.0 |

| 0.5 | – | ● | ● | ● | 0.9 | 11.5 | 3.0 |

| 0.6 | ● | ● | ● | ● | 0.9 | 11.5 | 3.0 |

| 0.8 | ● | ● | ● | ● | 0.5 | 11.5 | 3.0 |

| 1.0 | ● | ● | ● | ● | 0.5 | 11.5 | 3.0 |

| 1.2 | ● | ● | ● | ● | 0.6 | 11.5 | 3.0 |

| 1.5 | – | ● | ● | ● | 0.7 | 11.5 | 3.0 |

| 1.6 | ● | – | – | – | 0.8 | 11.5 | 3.0 |

| 2.0 | ● | ● | ● | ● | 1.0 | – | – |

| 2.3 | ● | – | – | – | 1.0 | – | – |

| 2.5 | – | ● | ● | ● | 1.2 | – | – |

| 3.0 | – | ● | ● | ● | 1.5 | – | – |

| 3.2 | ● | – | – | – | 1.5 | – | – |

| 4.0 | – | ● | ● | ● | 2.0 | – | – |

| 4.5 | ● | – | – | – | 2.2 | – | – |

| 5.0 | – | ● | ● | ● | 2.5 | – | – |

| 6.0 | ● | ● | ● | – | 3.0 | – | – |

| 9.0 | ● | ● | – | – | 4.0 | – | – |

| 10.0 | – | ● | – | – | 5.0 | – | – |

| 12.0 | – | ● | – | – | 6.0 | – | – |

穴と曲げの最小距離

鉄・圧延鋼板

ステンレス

アルミ

鉄・圧延鋼板

| 材質 | 板厚 | 穴種 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 通し穴 | 長穴・角穴 | タップ穴 | バーリングタップ | 皿穴 | ||||||

| 保証値a ※1 | 限界値a | 保証値a ※1 | 限界値a | 保証値a ※2 | 限界値a | 保証値a ※1 | 保証値a | 限界値a | ||

SS400 SPCC SPHC | 0.8 | 4.2 | 2.0 | 4.2 | 2.0 | – | – | 4.2 | – | – |

| 1.0 | 4.3 | 2.0 | 4.3 | 2.0 | 4.8 | 2.7 | 4.3 | – | – | |

| 1.2 | 5.5 | 3.0 | 5.5 | 3.0 | 6.0 | 3.9 | 5.5 | – | – | |

| 1.6 | 6.8 | 3.5 | 6.8 | 3.5 | 7.3 | 5.2 | 6.8 | – | – | |

| 2.0 | 8.0 | 4.0 | 8.0 | 4.0 | 8.7 | 6.6 | – | 8.0 | 4.0 | |

| 2.3 | 9.3 | 5.0 | 9.3 | 5.0 | 9.9 | 7.8 | – | 9.3 | 5.0 | |

| 3.2 | 13.3 | 6.5 | 13.3 | 6.5 | 13.8 | 11.7 | – | 12.1 | 6.5 | |

| 4.5 | 17.4 | 9.5 | 17.4 | 9.5 | 18.4 | 16.3 | – | 18.4 | 9.5 | |

| 6.0 | 23.5 | 14.0 | 23.5 | 14.0 | 24.5 | 22.4 | – | 24.5 | 16.0 | |

| 9.0 | 33.5 | 21.5 | 33.5 | 21.5 | 34.5 | 32.4 | – | 33.5 | 21.5 | |

| SECC | 0.8 | 4.2 | 2.0 | 4.2 | 2.0 | – | – | 4.2 | – | – |

| 1.0 | 4.3 | 2.0 | 4.3 | 2.0 | 5.3 | 3.2 | 4.3 | – | – | |

| 1.2 | 4.5 | 3.0 | 4.5 | 3.0 | 5.5 | 3.4 | 4.5 | – | – | |

| 1.6 | 5.8 | 3.5 | 5.8 | 3.5 | 6.8 | 4.7 | 5.8 | – | – | |

| 2.0 | 7.0 | 4.0 | 7.0 | 4.0 | 8.0 | 5.9 | – | 8.0 | 4.0 | |

| 2.3 | 8.3 | 5.0 | 8.3 | 5.0 | 9.3 | 7.2 | – | 9.3 | 5.0 | |

| 3.2 | 11.1 | 6.5 | 11.1 | 6.5 | 12.1 | 10.0 | – | 12.1 | 6.5 | |

ステンレス

| 材質 | 板厚 | 穴種 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 通し穴 | 長穴・角穴 | タップ穴 | バーリングタップ | 皿穴 | ||||||

| 保証値a ※1 | 限界値a | 保証値a ※1 | 限界値a | 保証値a ※2 | 限界値a | 保証値a ※1 | 保証値a | 限界値a | ||

SUS304-2B SUS304-#400 SUS304-HL SUS304-No.1 SUS430-2B | 0.8 | 4.2 | 2.0 | – | 4.2 | – | – | 4.2 | – | – |

| 1.0 | 4.3 | 2.0 | – | 4.3 | 5.3 | 3.2 | 4.3 | – | – | |

| 1.2 | 4.5 | 3.0 | – | 4.5 | 5.5 | 3.4 | 4.5 | – | – | |

| 1.5 | 6.0 | 3.5 | – | 6.0 | 7.0 | 4.9 | 6.0 | – | – | |

| 2.0 | 7.1 | 4.0 | – | 7.1 | 8.1 | 6.0 | – | 8.1 | 4.0 | |

| 2.5 | 11.3 | 6.3 | – | 11.3 | 12.3 | 10.2 | – | 12.3 | 6.3 | |

| 3.0 | 11.5 | 6.5 | – | 11.5 | 12.5 | 10.4 | – | 12.5 | 6.5 | |

| 4.0 | 17.2 | 11.5 | – | 17.2 | 18.2 | 16.1 | – | 18.2 | 11.5 | |

| 5.0 | 23.5 | 14.0 | – | 23.5 | 24.5 | 22.4 | – | 24.5 | 15.0 | |

| 6.0 | 25.0 | 19.0 | – | 25.0 | 26.0 | 24.0 | – | 26.0 | 17.0 | |

| 9.0 | 39.0 | 20.5 | 39.0 | 20.5 | 40.0 | 40.0 | – | 39.0 | 39.0 | |

| 10.0 | 46.5 | 22.5 | 46.5 | 22.5 | 47.5 | 47.5 | – | 46.5 | 46.5 | |

| 12.0 | 62.0 | 26.5 | 62.0 | 26.5 | 63.0 | 63.0 | – | 62.0 | 62.0 | |

アルミ

| 材質 | 板厚 | 穴種 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 通し穴 | 長穴・角穴 | タップ穴 | バーリングタップ | 皿穴 | ||||||

| 保証値a ※1 | 限界値a | 保証値a ※1 | 限界値a | 保証値a ※2 | 限界値a | 保証値a ※1 | 保証値a | 限界値a | ||

| A5052 | ||||||||||

| 0.8 | 4.2 | 2.0 | 4.2 | 2.0 | – | – | 4.2 | – | – | |

| 1.0 | 4.2 | 2.0 | 4.2 | 2.0 | 5.2 | 3.1 | 4.2 | – | – | |

| 1.2 | 4.3 | 2.5 | 4.3 | 2.5 | 5.3 | 3.2 | 4.3 | – | – | |

| 1.5 | 6.0 | 3.5 | 6.0 | 3.5 | 7.0 | 4.9 | 6.0 | – | – | |

| 2.0 | 7.1 | 4.0 | 7.1 | 4.0 | 8.1 | 6.0 | – | 8.1 | 4.0 | |

| 2.5 | 10.0 | 4.5 | 10.0 | 4.5 | 11.0 | 9.0 | – | 10.5 | 4.5 | |

| 3.0 | 11.5 | 5.0 | 11.5 | 5.0 | 12.5 | 10.4 | – | 12.5 | 5.0 | |

| 4.0 | 17.2 | 11.5 | 17.2 | 11.5 | 18.2 | 16.1 | – | 18.2 | 11.5 | |

| 5.0 | 17.9 | 12.0 | 17.9 | 12.0 | 18.9 | 16.8 | – | 18.9 | 12.0 | |

| 6.0 | 23.0 | 13.0 | 23.0 | 13.0 | 24.0 | 21.0 | – | 23.0 | 13.0 | |

内角90°未満の鋭角曲げ形状の場合、保証値範囲内であっても加工不可になる場合があります。

※1 保証値を下回った場合、穴が変形する恐れがあります。

それに伴い寸法も不正確になりますが、そのまま加工します。

※2 保証値を下回った場合、リタップ加工となり、遊びが生じる恐れがあります。

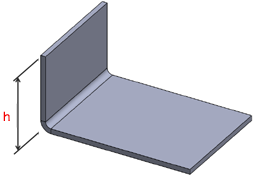

最小曲げ高さ

鉄・圧延鋼板

ステンレス

アルミ

鉄・圧延鋼板

| 材質 | 板厚 | 限界値h |

|---|---|---|

SS400 SPCC SPHC | 0.8 | 4.2 |

| 1.0 | 4.3 | |

| 1.2 | 5.5 | |

| 1.6 | 6.8 | |

| 2.0 | 8.2 | |

| 2.3 | 9.4 | |

| 3.2 | 13.3 | |

| 4.5 | 17.4 | |

| 6.0 | 23.5 | |

| 9.0 | 33.5 | |

| SECC | 0.8 | 4.2 |

| 1.0 | 4.3 | |

| 1.2 | 4.5 | |

| 1.6 | 5.8 | |

| 2.0 | 7.0 | |

| 2.3 | 8.3 | |

| 3.2 | 11.1 |

ステンレス

| 材質 | 板厚 | 限界値h |

|---|---|---|

SUS304-2B SUS304-#400 SUS304-HL SUS304-No.1 SUS430-2B | 0.8 | 4.2 |

| 1.0 | 4.3 | |

| 1.2 | 4.5 | |

| 1.5 | 6.0 | |

| 2.0 | 7.1 | |

| 2.5 | 11.3 | |

| 3.0 | 11.5 | |

| 4.0 | 17.2 | |

| 5.0 | 23.5 | |

| 6.0 | 25.0 | |

| 9.0 | 39.0 | |

| 10.0 | 46.5 | |

| 12.0 | 62.0 |

アルミ

| 材質 | 板厚 | 限界値h |

|---|---|---|

| A5052 | 0.8 | 4.2 |

| 1.0 | 4.3 | |

| 1.2 | 4.5 | |

| 1.5 | 6.0 | |

| 2.0 | 7.1 | |

| 2.5 | 10.0 | |

| 3.0 | 11.5 | |

| 4.0 | 17.2 | |

| 5.0 | 17.9 | |

| 6.0 | 23.0 |

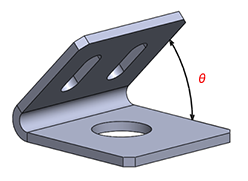

鋭角曲げの最小角度

鋭角曲げの角度θ は 45°以上にしてください。

ただし、以下の材質・板厚についてはθの要件が異なりますので、ご確認ください。

鉄・圧延鋼板

ステンレス

アルミ

鉄・圧延鋼板

| 材質 | 板厚 | 鋭角曲げ角度 |

|---|---|---|

| SS400 | 9.0 | θ ≧ 88° |

| SPHC | 4.5 | |

| 6.0 |

ステンレス

| 材質 | 板厚 | 鋭角曲げ角度 |

|---|---|---|

| SUS304-2B | 6.0 | θ ≧ 50° |

| SUS304-No.1 | 9.0 | θ ≧ 88° |

| 10.0 | ||

| 12.0 |

アルミ

| 材質 | 板厚 | 鋭角曲げ角度 |

|---|---|---|

| A5052 | 2.5 | θ ≧ 60° |

| 3.0 | ||

| 4.0 | ||

| 5.0 | ||

| 6.0 | θ ≧ 88° |

穴の最小コーナーR

穴のコーナーRを指定する場合は、0.5mm以上にて設計してください。